Aluminum foil roll|How does the aluminum foil slitting machine perform slitting work

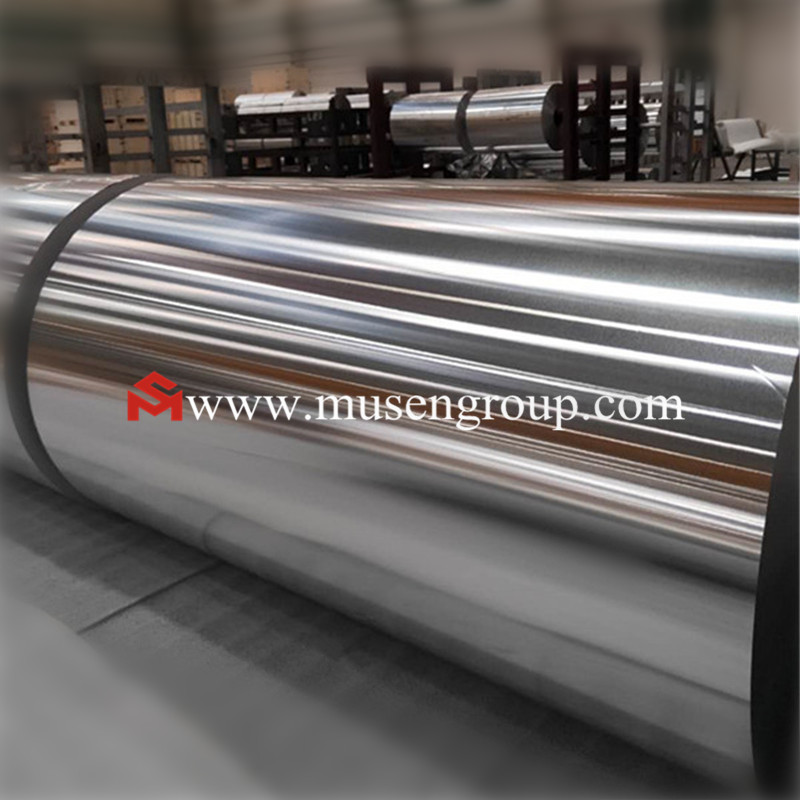

aluminum foil roll

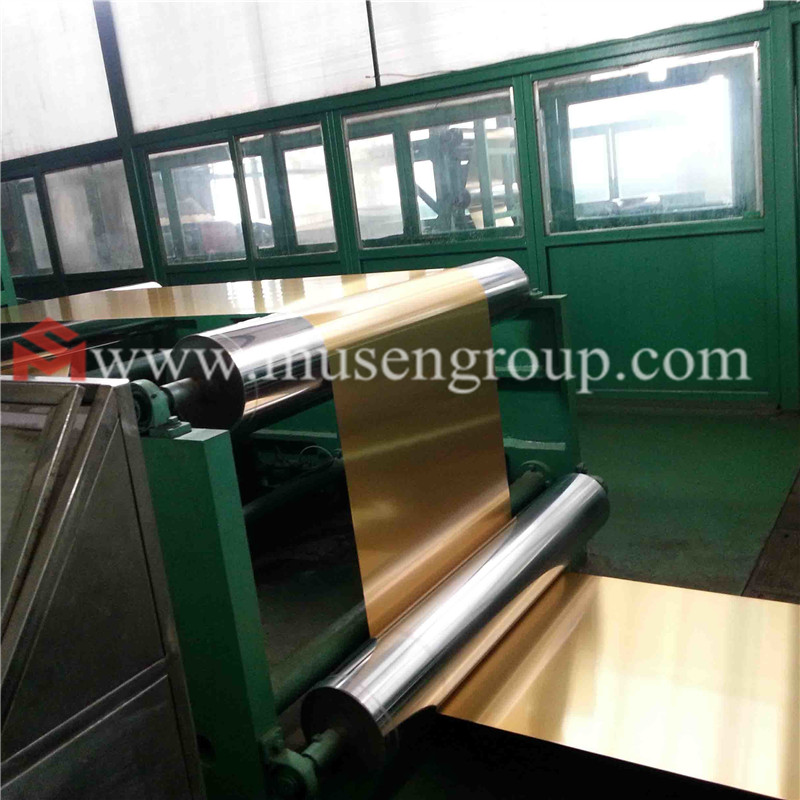

The basic working principle: the aluminum foil needs to be slit after printing on the slitting machine, and the large semi-finished product is cut into the required specifications. The semi-finished product that runs on the slitting machine is a process of unwinding and rewinding. The process includes two parts: machine speed control and tension control.

The winding and unwinding tension setting of the equipment directly affects the yield of the product. If the tension is too large, the winding is too tight, and the aluminum foil is prone to wrinkles; if the tension is insufficient, the aluminum foil is likely to slip on the roll and cause serious misalignment. Unloading, and causing the unwinding shaft to swing greatly during slitting, which affects the quality of slitting, so the slitting machine must have a good tension detection system.

Slitting process: First, the aluminum sheet is rolled by a cold rolling mill, an aluminum foil roughing mill, and an aluminum foil finishing rolling mill to form a double layer of 0.03~0.006mm aluminum foil. Then, the double-layer aluminum foil is separated by the aluminum foil slitting machine, and at the same time, the 1000~1850mm wide aluminum foil is slit into several aluminum foils of different widths according to different commercial requirements, and they are rolled into aluminum coils according to a constant tension method.