Aluminum Cast Plate

Casting is a metal thermal process that is a method of casting liquid metal into a casting cavity that fits the shape of the part and leaving it to cool and solidify in order to obtain a part or blank.

As one of the basic processes of the modern manufacturing industry, casting can reduce production time and thus the production cost to a certain extent.

Aluminum Casting

Aluminum is one of the excellent materials for mold casting. The aluminum casting process is a process in which pure aluminum or aluminum alloy liquid is poured into the mold cavity and cooled to form aluminum parts of the desired shape.

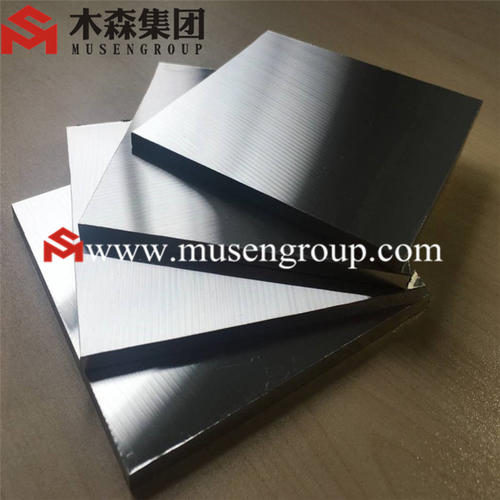

Aluminum Cast Plate

As the name implies, the aluminum cast plate is an aluminum sheet obtained by the casting method. Aluminum products with a thickness of more than 10mm can usually be obtained by casting.

Aluminum cast plates are mainly used to obtain aluminum products with more complex textured decorative patterns on the surface and are suitable for products with certain thickness requirements for aluminum plates.

Aluminum cast plates are widely used in the production of armored security doors, and in recent years they have also been gradually used for building facades.

ACP5080 Aluminum Cast Plate

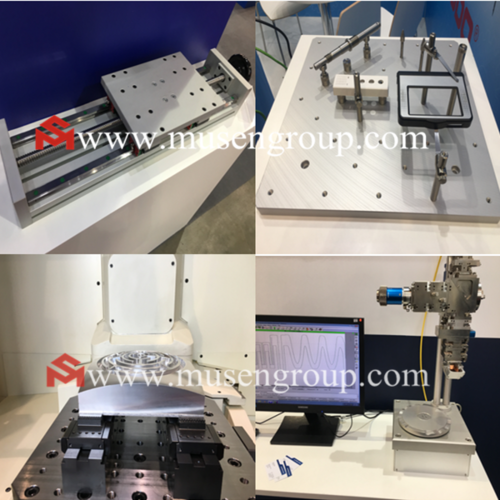

With a precision surface machined on both sides, ACP5080 is also called an Ultra-Flatness Precision Aluminum Plate in China. Thickness, flatness, and surface finish offer very tight tolerances.

Material stability and excellent processing characteristics make this ACP5080 aluminum cast plate the right choice for fixtures, tools, and general applications. They are usually used in small cutting sizes like 100*200mm,200*300mm, etc.

MIC-6 Aluminum Cast Plate

The high-precision aluminum cast plate MIC-6 Aluminum Cast Plate is a chemical composition similar to 7000 series alloy. MIC-6 aluminum cast plate promotes consistency between plates and reduces the risk of disrupting material stability by entrapping stress.

MIC-6 aluminum cast plate commonly applies in Machine Components, Aerospace and Automotive Components, Electronics, Laser Technology, and Optical industries.

Aluminum Casting Method

Cast aluminum plates are generally cast by sand casting. Other common ways of casting aluminum are die-casting, low-pressure casting, precision casting, permanent mold casting, etc.

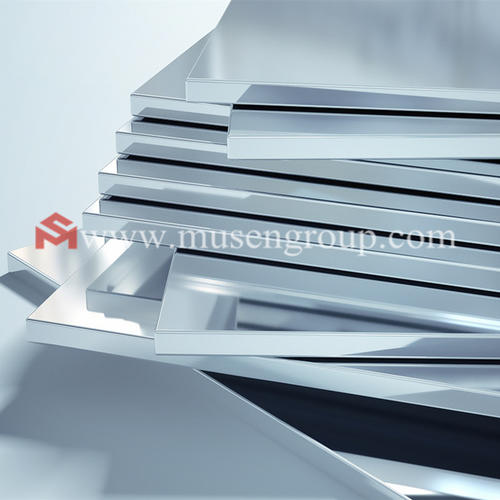

Aluminum Cast Plate & Traditional Aluminum Veneer

Different from the traditional aluminum veneer facades, cast aluminum panels have a certain strength. Compared with the conventional aluminum curtain wall, the thickness of cast aluminum plate can be customized according to the needs, and the conventional size has 6mm, 8mm, and 10mm aluminium plates, and thicker special sizes.

Conclusion

Aluminum cast plate provides excellent stability and consistency from plate to plate, with excellent flatness and dimensional tolerances in thickness.

MUSEN aluminum cast plates meet industry-leading tight tolerance standards. Most of our aluminum cast plates such as High Precision Aluminum Cast Plate, ACP5080 Aluminum Cast Plate, and MIC-6 Aluminum Cast Plate are available in full size and custom cut lengths.